About cement stamp mold hardness

News 2023年12月21日 194

The hardness of a cement stamp mold refers to its resistance to indentation or deformation. It is an important factor to consider when choosing a stamp mold because it affects the durability and quality of the stamped concrete.

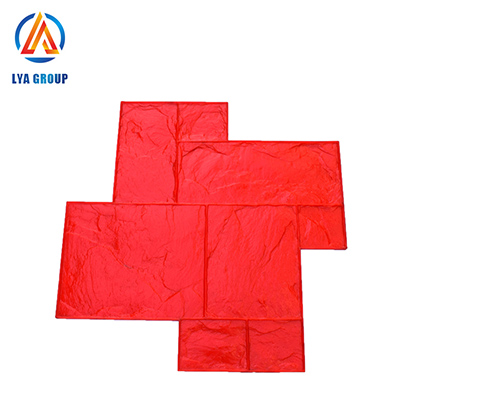

Stamp molds are typically made from various materials such as polyurethane, rubber, or silicone. The hardness of the mold is determined by the material used and its formulation. Different manufacturers may offer molds with varying hardness levels to suit different applications and preferences.

The hardness of a stamp mold is usually measured on a durometer scale. The durometer scale provides a numerical value that represents the mold’s hardness. The most commonly used durometer scales for measuring the hardness of stamp molds are the Shore A and Shore D scales.

Shore A Scale: This scale is used for measuring the hardness of softer materials such as rubber or polyurethane. The higher the numerical value on the Shore A scale, the harder the material. For example, a stamp mold with a Shore A hardness of 70 is harder than a mold with a Shore A hardness of 50.

Shore D Scale: This scale is used for measuring the hardness of harder materials such as rigid plastics or some types of rubber. Similarly, a higher numerical value on the Shore D scale indicates a greater hardness.

The choice of hardness for a cement stamp mold depends on several factors, including the type of concrete surface you want to create and the specific design or pattern of the stamp. Here are some general guidelines:

1.High Hardness: Molds with higher hardness are generally more suitable for creating detailed patterns or designs with sharp edges and intricate textures. They provide better definition and durability, especially when working with abrasive aggregates or heavy traffic areas.

2.Medium Hardness: Molds with medium hardness are versatile and can be used for a wide range of stamping projects. They offer a good balance between detail definition and flexibility, making them suitable for both residential and commercial applications.

3.Low Hardness: Molds with lower hardness are more flexible and forgiving. They are ideal for stamping irregular or curved surfaces, as they can conform better to the contours. However, they may be less resistant to wear and tear over time.

It’s important to note that the hardness of the stamp mold should be compatible with the characteristics of the concrete mix and the stamping process. Working with a professional supplier or manufacturer can help you choose the appropriate hardness level based on your specific requirements and the conditions of your project.